3d print not extruding fast enough

It interprets g-code commands controls the stepper motors and is in charge to control the temperatures. Unlike Marlin the most popular 3d printer firmware Klipper is meant to work with a 3D printer mainboard alongside an additional.

How To Fix Under Extrusion Maintenance And Print Settings

Surprisingly enough the rectilinear infill pattern happens to be very efficient in terms of plastic use so it prints faster than honeycomb 30 faster and a few other patterns out there.

. Honeycomb cubic is probably the most popular 3D printing infill pattern out there. Take a piece of letter paper normal weight and fold it in half. We have compiled an extensive list of the most common 3D printing issues along with the software settings that you can use to solve them.

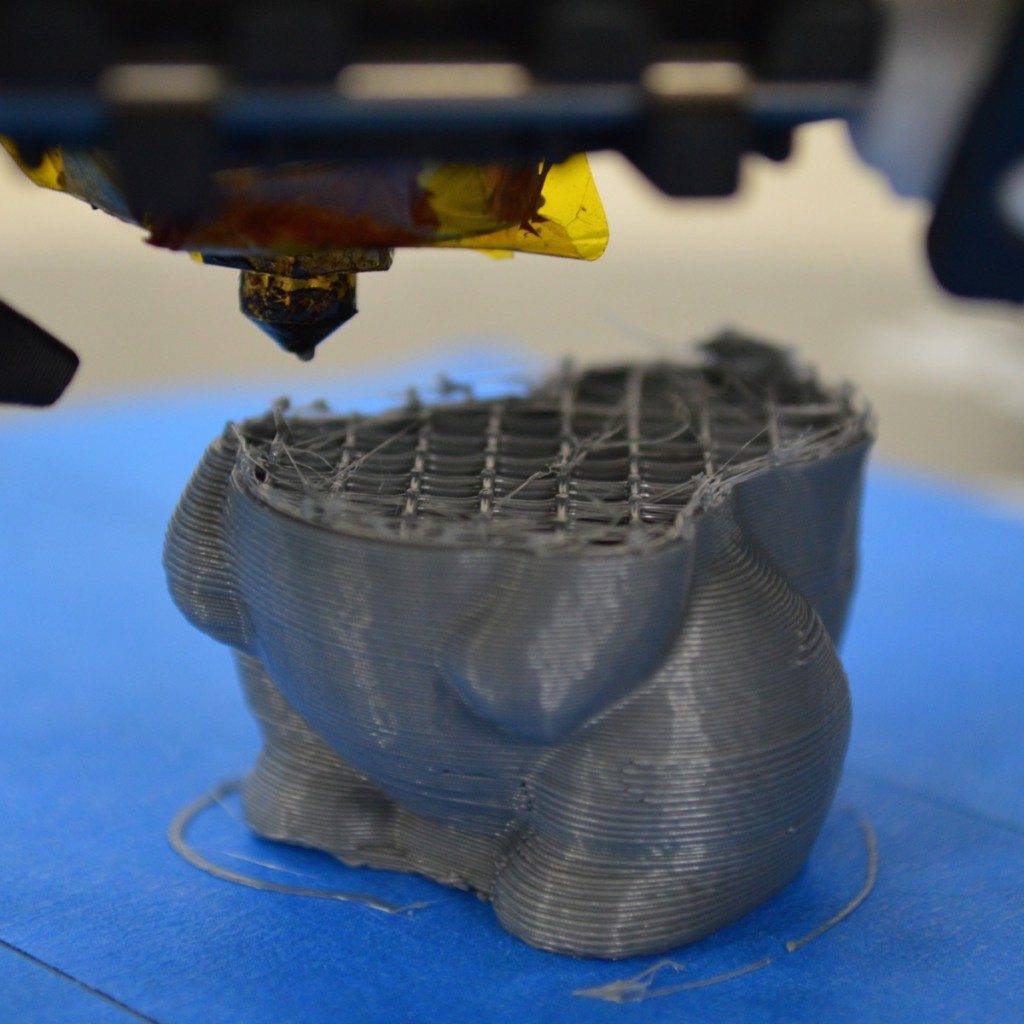

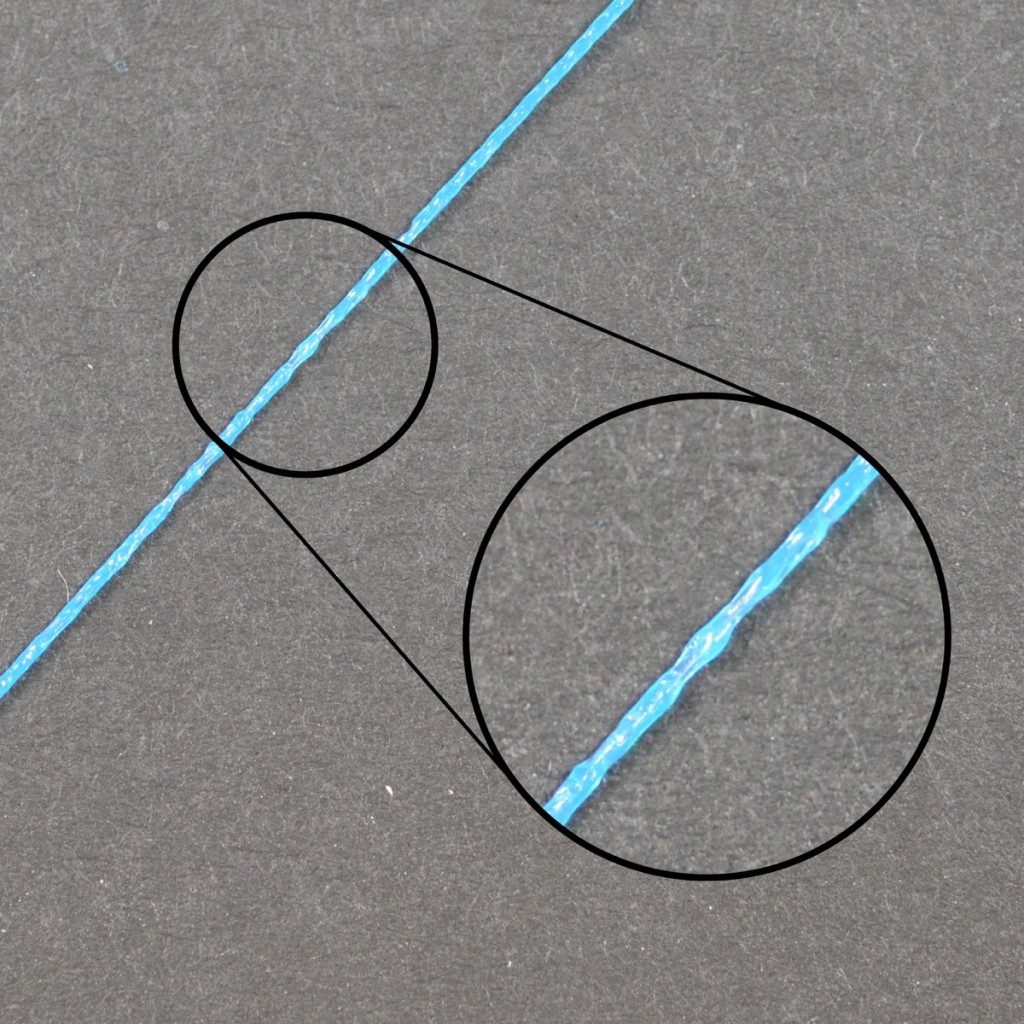

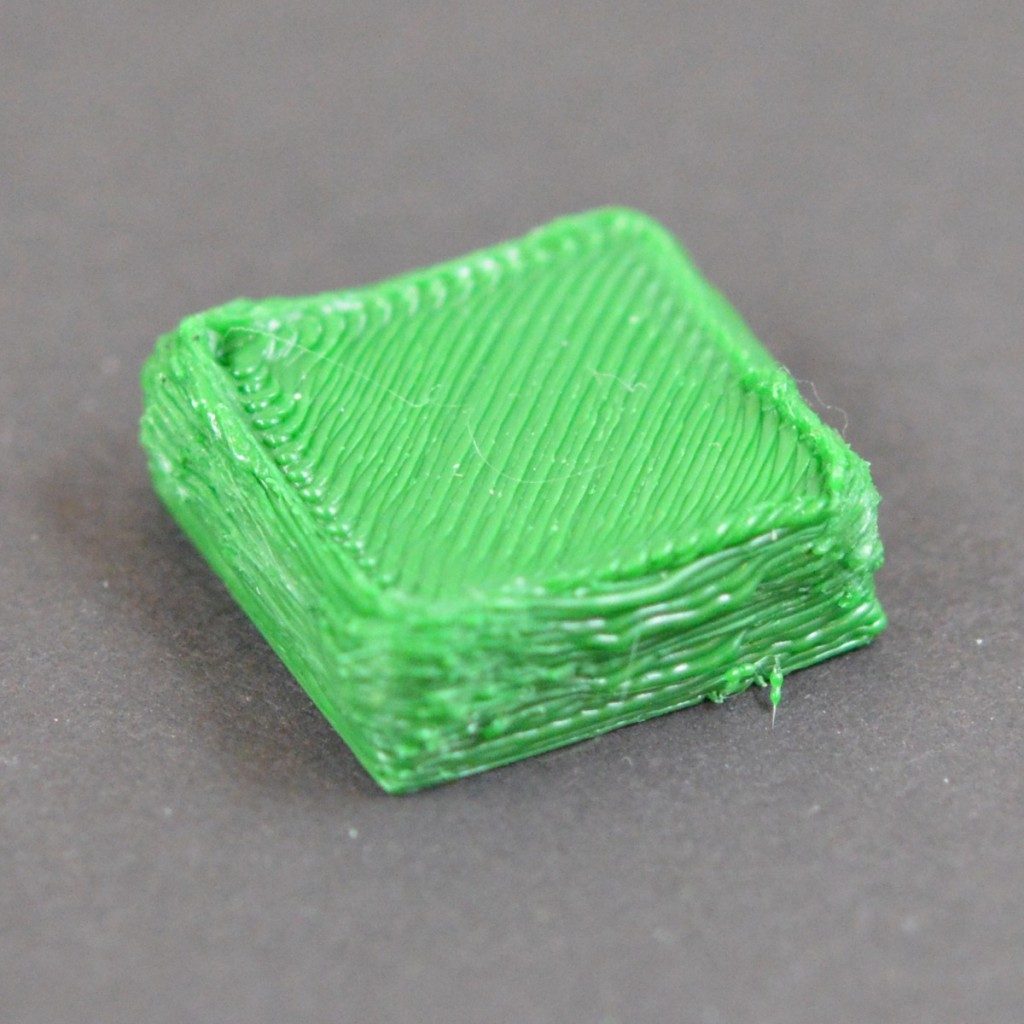

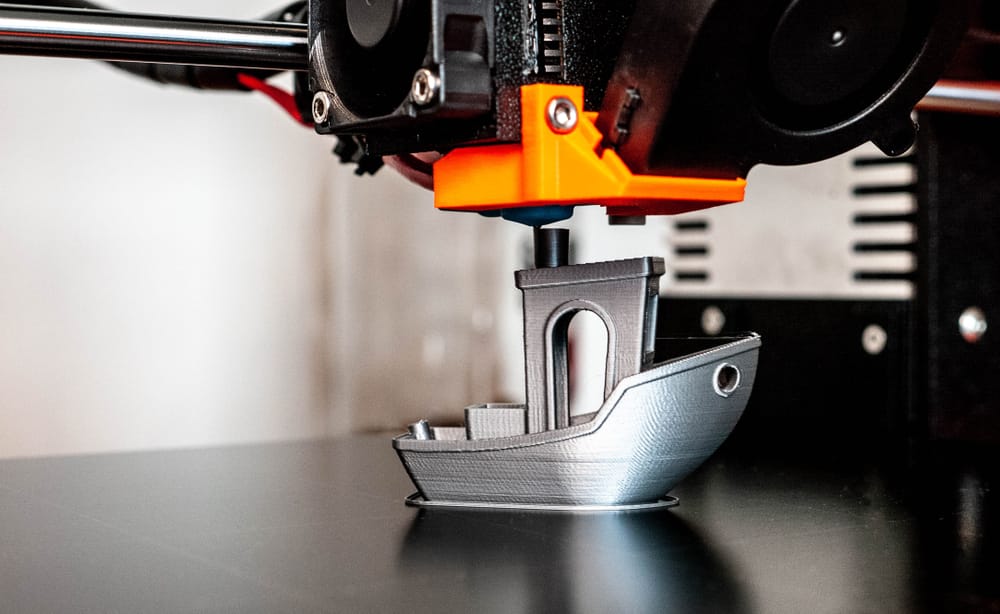

Best of all the guide uses a large collection of real-world images. Bed Temperature ASA requires a heated bed set at 80C -100C. This guide is a great place to start if you are trying to improve the quality of your 3D printed parts.

Still the results might change with each new design or material and the chance of failed prints remains high. Delete interior faces Select-- Interior Faces. Upload your model and get a free quote or instantly place an order online.

Self-compacting concrete may not be suitable for 3D printing as it may not hold its shape in the formwork-free method of 3D printing. Now select the parts which are the ngons. Therefore optimal speed depends on the object you are printing and the filament material that you are using to fabricate the object.

At Solidium3D were proud to be your local 3D Printing Service with fast delivery and local support. Longer LK5 Pro 3D Printer FDM Large Size 3D Printer 118x118x157 Inch Big Print Size 90 Pre-Assembled Dual Blower Kit Silent Motherboard for DIY Home School Printing Sovol SV01 Pro 3D Printer with Metal Direct Drive Extruder CR-Touch Silent Board Dual Z-axis 43 inch Handheld Color Touch Screen Flexible Magnetic Plate Larger Build Volume 11x95x118 inch. You can 3D print your own footwear with TPU filament.

Also it is not necessary to adjust the retraction speed equal to your print speed. Place it under your 3D printers nozzle and home the hotend onto the paper. When some of my 3D prints came off the bed.

As an example pumpable concrete may not have enough shape-stability and dimensional accuracy after printing even though it is good for the extrusion process of 3D printing. SainSmart TPU will not disappoint if you are looking for flexible filament. If the print bed and the first layer settings are not properly adjusted and calibrated the 3D print can fail or fall over.

SainSmart TPU gains popularity among 3D Printing community for its balance of rigidity and flexibility. Printing fast without enough cooling. Print speed is how fast the print head travels while extruding filament.

Poorly Leveled Print Bed or First Layer Settings. Check the Extruder Temperature. Unlike traditional printers where both extruders are locked into the same task the M3-IDs extruders work independently and.

If the nozzle temperature isnt hot enough you may experience compromised mechanical properties due to the poor layer adhesion under-extrusion uneven rough surface quality and if the filament is not melting fast enough. The best setting is to keep it as fast as possible without leading to the grinding of the filament with your drive gear. To level a 3D Printers build plate AKA print bed you will need.

Photon Mono SE LCD 149 Was 342 Delivered AnyCubic eBay Store. TPU and other flexible filaments can be difficult to print with. TPU filament has a high degree of abrasion resistance making it durable against damage.

Initially wanted to go for another. Because they are so elastic some 3D printers have difficulty pushing. Press ShiftH to see only selected parts in 3d view.

A Piece of Paper. Like Marlin it is the piece of software that controls all the hardware in your 3d printer. This article has been written to provide both printing and troubleshooting tips along with tips for post-printing processes like painting and support removal.

NoteThis video is not mine and I take no credit for it. When extruding the. A good 3D print starts from the ground up.

The MakerGear M3-ID is the first desktop 3D printer to fully support duplication printing with independent extruders. This not only delays projects but can also lead to messy failures that require a lengthy cleanup process. We have highlighted important topics with a star so please dont feel intimidated as sections in this guide may not be relevant to.

Klipper is an alternative 3d printer firmware. Print Quality Troubleshooting Guide. AnyCubic Resin 3D Printer.

A lot of 3D printer users will. Low-cost FDM or SLA 3D printers are not really user friendly and often require many hours of tweaking and experimenting to dial-in the correct print settings. Therefore you must find ways to avoid them.

Electrical -. It may not be the super fast method but in case of huge objects it could be useful. Of course a sight of these blobs and zits is not great to look at especially that we try to produce 3D prints that are flawless and high quality as much as possible.

A 3D Printer. In general simple objects with less detail can be printed faster without complication. An Allen Key.

When 3D printing most of the game depends on temperature settings. In addition with a 95A Shore Hardness and improved bed adhesion it is easier to print even with a stock elementary 3D Printer like the Creality Ender 3. It is also resistant to substances like oil grease and several different chemicals.

Also layer-by-layer appearance anisotropic. It is important your heated bed isnt set above the. The best all-round infill pattern has to be honeycomb otherwise known as cubic.

Authors Note Thankyou for taking the time to read our guide on 3D printing PETG. Select the whole object and choose Mesh-- Clean up-- Fill Holes Select the whole mesh unwrap it using Smart UV Project and click the sync button. SL is a process in which a light source of a certain wavelength usually in the ultraviolet range is used to selectively cure a.

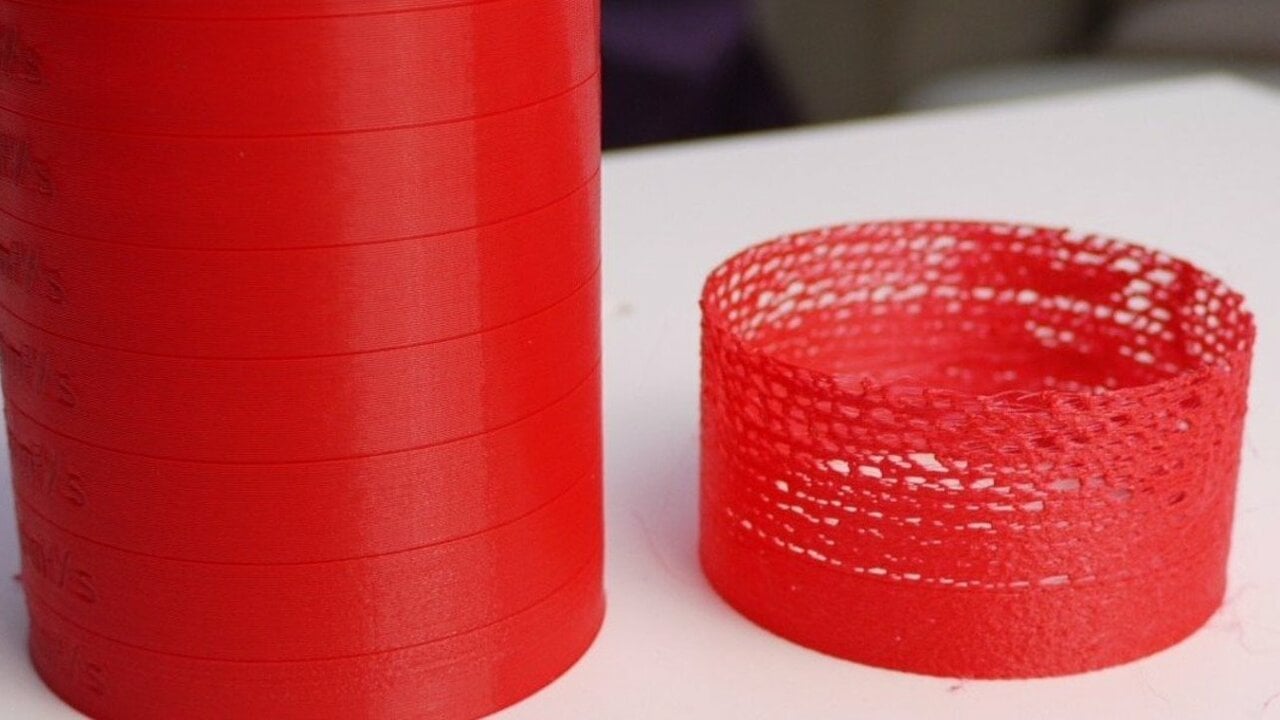

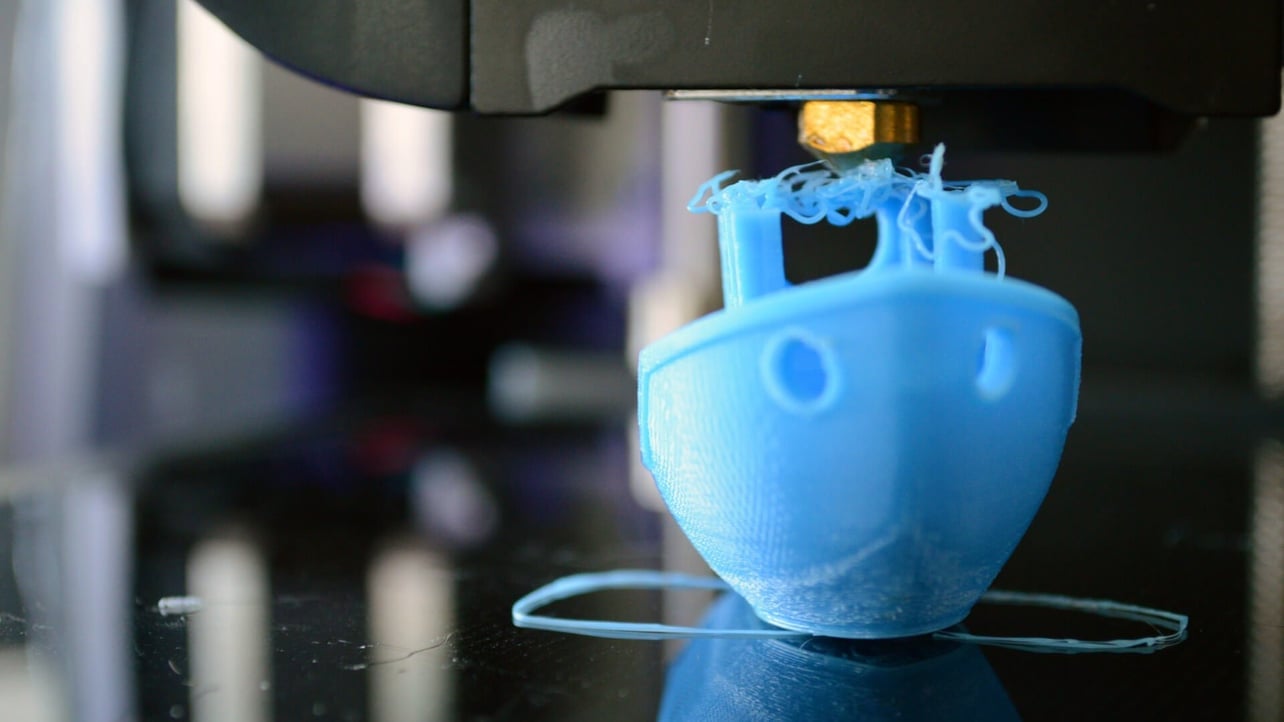

Printing a Benchy at 580 scale on the Anet ET5X 300x300x400mm Build Plate Printing in Vase Mode with a Large Nozzle. We always aim for the best quality and reliable results. Example of blobs and zits in a finished print.

The SL technique is believed to be the most prominent and popular 3D printing technology and has been extensively used worldwide It was first proposed and developed by Hull in 1986 and was later commercialised by 3D Systems Inc. When using a 8mm nozzle its also possible to utilize Vase Mode 3D Printing also known as Spiralized Contour where the print slicer software creates a toolpath that traces the outer contour of the model and only prints in a single helical toolpath. Lets look at some of these issues in detail.

After 35 hours of testing we think our easy-to-use comfortable full-featured pick is the best tool for drawing 3D sculptures. In the meantime lets discuss further what can be the other possible causes why. We will 3D print your model and send out within 1-4 business days depends on the models and the quantity.

Under Extrusion How To Deal With It In 3d Printing Two Trees

How To Solve The Most Common 3d Printing Problems 3d Printing Prints Visual

Why Are There Gaps In 3d Print In 2022 3d Printing Print Gap

3d Printing Troubleshooting Guide Part Not Extruding Youtube

3d Printing Inconsistent Extrusion Troubleshooting 3d Newb

How To Solve The Most Common 3d Printing Problems 3d Printing For Beginners Prints 3d Printing 3d Printing Machine

Reprap Under Extrusion Towards The End Of The Print 3d Printing Stack Exchange

8 Ways How To Fix A Clicking Slipping Extruder On A 3d Printer 3d Printerly

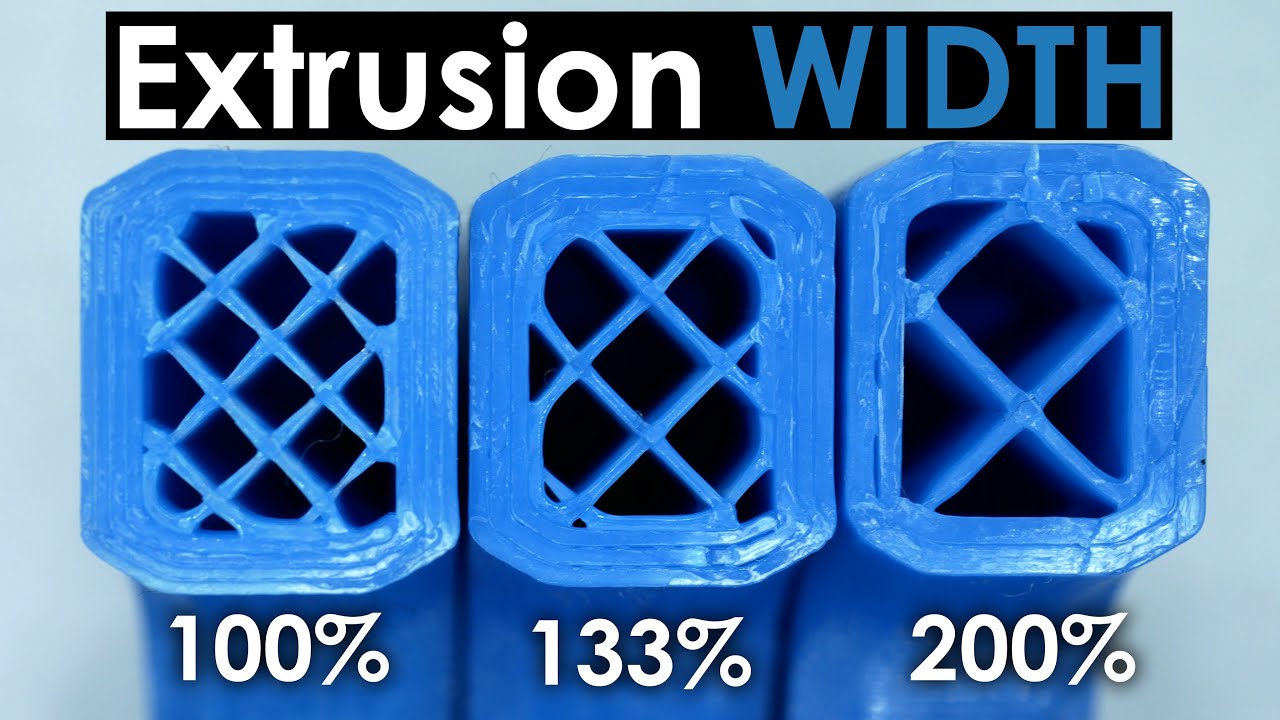

3d Printer Line Extrusion Width Best Settings Examples

3d Printer Under Extrusion 8 Simple Solutions All3dp

Not Extruding At Start Of Print

3d Printing Troubleshooting Common 3d Printing Problems All3dp

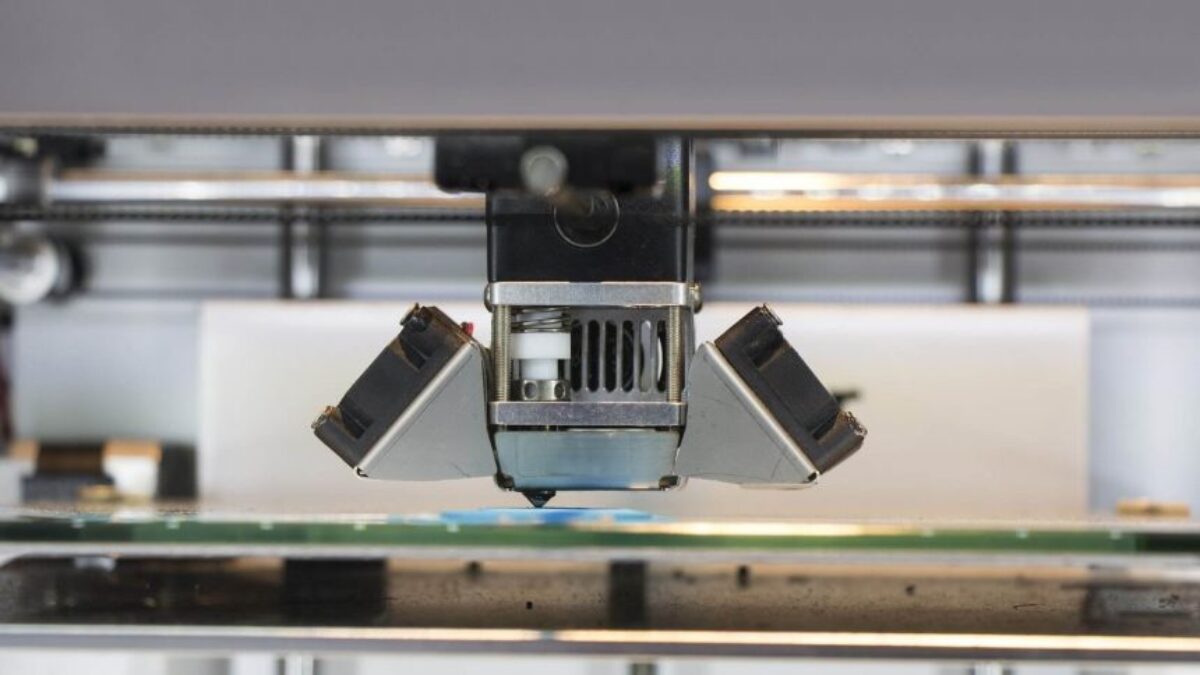

Extruder Essential Part Of A 3d Printer